Korea seeks carbon neutrality through LG, SK’s biodegradable plastic

By Kim Byung-wookPublished : Dec. 9, 2020 - 17:10

South Korea has rolled up its sleeves to support the domestic biodegradable plastic industry to address carbon-intensive plastic products and achieve carbon neutrality by 2050.

According to the recent “White Biotechnology Industry Revitalization Strategy” released by the Ministry of Trade, Industry and Energy, the government will create demand for biodegradable plastic products, which are two to three times more expensive than conventional plastic items. The fall in prices of oil and raw materials during the pandemic has made conventional plastics even cheaper.

“Typical plastic bottles, after buried underground, take some 450 years until they are completely decomposed, while it takes just six months to five years for biodegradable plastic products,” an Industry Ministry official said.

Biodegradable plastic has not been commercialized in Korea, as the tiny domestic market discourages petrochemical companies from making large investments and reaching an economy of scale.

Korea’s bioplastic production in 2018 actually decreased from 2016 to 48.9 billion won ($45.1 million). Korea’s market share in the global bioplastic market was 1.5 percent as of 2018, according to the Industry Ministry.

To prop up the sector, the government will collaborate with petrochemicals companies to develop prototype biodegradable plastic products such as disposable spoons and plates. Then, the government will test the economic feasibility by deploying them at public facilities such as stadiums and theaters where retrieval is easy. Also, additional infrastructure will be established to process the retrieved plastic products.

Moreover, the government is mulling plans to provide subsidies to customers if they switch to plastic products made of bio raw materials such as corn and starch.

According to the recent “White Biotechnology Industry Revitalization Strategy” released by the Ministry of Trade, Industry and Energy, the government will create demand for biodegradable plastic products, which are two to three times more expensive than conventional plastic items. The fall in prices of oil and raw materials during the pandemic has made conventional plastics even cheaper.

“Typical plastic bottles, after buried underground, take some 450 years until they are completely decomposed, while it takes just six months to five years for biodegradable plastic products,” an Industry Ministry official said.

Biodegradable plastic has not been commercialized in Korea, as the tiny domestic market discourages petrochemical companies from making large investments and reaching an economy of scale.

Korea’s bioplastic production in 2018 actually decreased from 2016 to 48.9 billion won ($45.1 million). Korea’s market share in the global bioplastic market was 1.5 percent as of 2018, according to the Industry Ministry.

To prop up the sector, the government will collaborate with petrochemicals companies to develop prototype biodegradable plastic products such as disposable spoons and plates. Then, the government will test the economic feasibility by deploying them at public facilities such as stadiums and theaters where retrieval is easy. Also, additional infrastructure will be established to process the retrieved plastic products.

Moreover, the government is mulling plans to provide subsidies to customers if they switch to plastic products made of bio raw materials such as corn and starch.

The state-led push for biodegradable plastic is expected to boost LG, SK, CJ and Lotte’s bioplastic businesses.

In October, LG Chem developed a biodegradable plastic made of glucose from corn and waste glycerol generated from biodiesel production. Though made 100 percent with biodegradable raw materials, the new plastic is identical to synthetic plastic in its properties and functions, according to the company. LG Chems aims for mass production in 2025.

SKC, a chemical and tech material unit under SK Group, will begin commercial production of well-known biodegradable plastic called PBAT with enhanced durability starting next year. Meanwhile, SK Chemicals will start the construction of a PO3G plant within this year. PO3G is an eco-friendly material from 100 percent bio raw materials made from fermented corn and is used for making clothes and shoes.

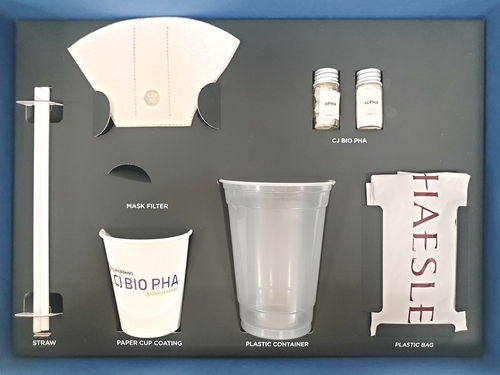

CJ Cheiljedang, the country’s top food maker, plans to mass produce PHA starting next year and establish an annual production capacity of 5,000 tons in Indonesia. PHA is the only biodegradable material that is decomposed 100 percent in seawater.

Also, demand for Lotte Chemical’s bio-PET, which is made of sugarcane, has increased significantly lately. Sales of the material spiked more than six times last year compared to a year prior, according to the company.

By Kim Byung-wook (kbw@heraldcorp.com)

![[Hello India] Hyundai Motor vows to boost 'clean mobility' in India](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/25/20240425050672_0.jpg&u=)