Samsung affiliate announces 5 new MLCCs for automobiles

By Song Su-hyunPublished : July 12, 2020 - 15:43

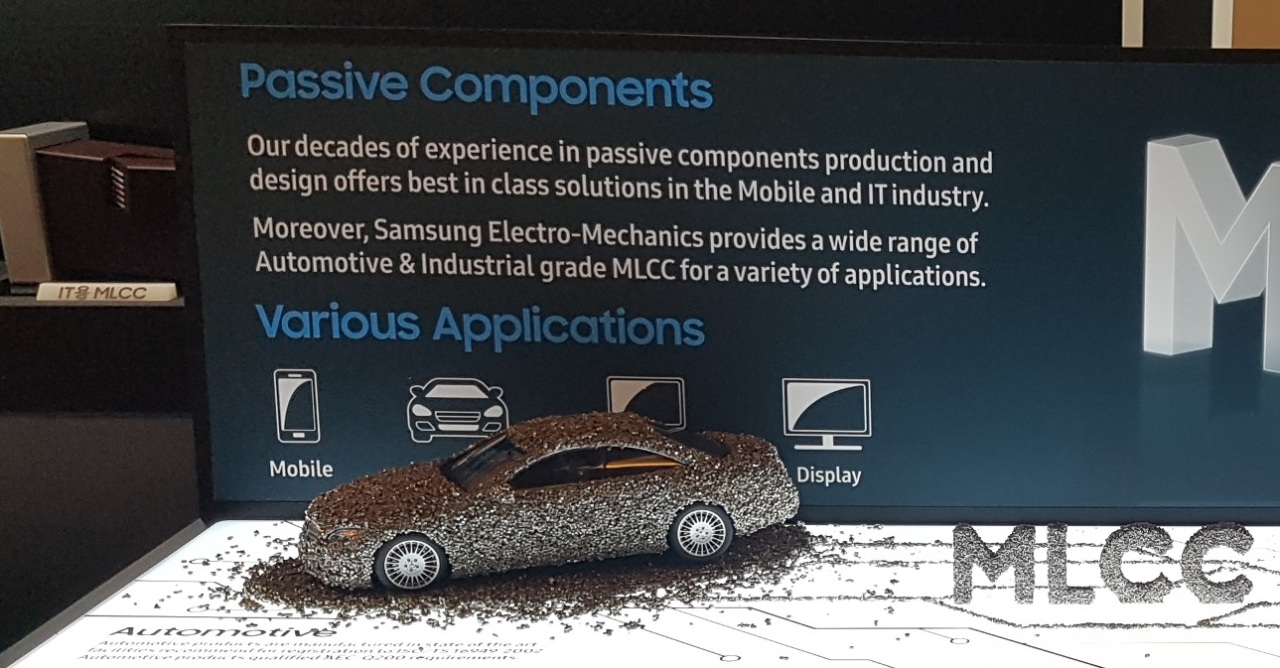

Samsung Electro-Mechanics, an electronic parts supplier affiliated with Samsung Electronics, has developed five new types of multi-layer ceramic capacitors for automobiles, expanding its automotive MLCC lineup to further penetrate into the global market, the company said Sunday.

MLCC is an essential part for electronics, which controls electric currents to flow at stable levels, supply needed amounts of power for chips, and remove noise inside products.

The capacitor, known as the tiniest part of electronics, is as thin as human hair -- 0.4 millimeter by 0.2 mm -- and at least 1,000 capacitors are needed for today’s smartphones per unit, and about 3,000 to 10,000 capacitors are needed for one vehicle.

The Samsung unit has come up with three MLCCs for powertrain and two for anti-lock brake system, which will be supplied for global automakers.

Considering that the powertrain in a vehicle requires endurance to high temperatures and pressures, the MLCC technologies for the automotive part are one of the highest-levels.

Samsung has developed three sizes -- 2.0 mm by 1.2 mm, 3.2 mm by 1.6 mm, and 3.2 mm by 2.5 mm. The smallest one offers 1.0 microfarad, while the bigger ones offer 2.2 and 4.7 microfarad each.

The company highlighted it used its proprietary ceramic and other electrode materials and ultra-precise stacking method to cope with a supply of up to 100 volts.

The average voltage used for electronic systems in vehicles is increasing from 12 volts to 48 volts as they become more connected and sophisticated, the firm noted.

The two MLCCs for the anti-lock brake system have improved the parts’ lifespan by 20 percent compared to existing ones and safety by 5 percent, it said.

Since the ABS in a car directly affects passengers’ safety, trust in product quality is the most crucial, the company said.

“Development and mass production of automotive MLCCs require high-level technologies,” said Kim Doo-young, executive vice president at Samsung Electro-Mechanics. “Samsung will provide differentiated material and process technologies, offering competitive products for customers with the latest lineup.”

Samsung started its automotive MLCC business in 2016, and is producing the products at its manufacturing facility in Busan since 2018. It is currently building another production facility in Tianjin, China.

By Song Su-hyun (song@heraldcorp.com)

![[KH Explains] How should Korea adjust its trade defenses against Chinese EVs?](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/15/20240415050562_0.jpg&u=20240415144419)

![[Today’s K-pop] Stray Kids to return soon: report](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/16/20240416050713_0.jpg&u=)