‘Game changer’ in guardrail industry taps overseas roads

Caris Guardrail acknowledged as world’s 1st PVC guardrail maker

By Kim Yon-sePublished : Dec. 23, 2018 - 20:33

Local enterprise Caris Guardrail Co. has been drawing global attention for its recent development of safe, eco-friendly guardrails, which have passed various tests for commercialization in both South Korea and the US.

It began as a venture startup founded by Yu Cheol in May 2016.

Its PVC (polyvinyl chloride)-based guardrails received venture business certification and green certification, and passed the domestic vehicle collision test and the US vehicle collision test in June 2018.

The company said it obtained the world’s first patent for PVC-composite guardrails. Alongside its original function of protecting major facilities around roads, vehicles, drivers and pedestrians, the product is made from eco-friendly materials on the basis of state-of-the-art technologies, which is not only beneficial to humans but the environment as well.

Last month, Caris Guardrail became the world’s first firm to receive the Innovative Award in the guardrail segment from the International Road Federation.

Founder and CEO Yu said the company has been recognized as an innovative manufacturer around the world, and the award has further boosted the company in the global market.

It began as a venture startup founded by Yu Cheol in May 2016.

Its PVC (polyvinyl chloride)-based guardrails received venture business certification and green certification, and passed the domestic vehicle collision test and the US vehicle collision test in June 2018.

The company said it obtained the world’s first patent for PVC-composite guardrails. Alongside its original function of protecting major facilities around roads, vehicles, drivers and pedestrians, the product is made from eco-friendly materials on the basis of state-of-the-art technologies, which is not only beneficial to humans but the environment as well.

Last month, Caris Guardrail became the world’s first firm to receive the Innovative Award in the guardrail segment from the International Road Federation.

Founder and CEO Yu said the company has been recognized as an innovative manufacturer around the world, and the award has further boosted the company in the global market.

“They have called us a ‘game changer,’ which is the highest praise,” he said.

After the company won the 2018 IRF Global R2T Conference & Expo Innovative Award in Las Vegas, many foreign agencies and buyers visited the Korean company’s booth, which led to trade contracts between Caris Guardrail and foreign governments and enterprises.

In addition, the company received the Ministry of Trade, Industry and Energy’s Innovation-promotion Award in Korea this month.

On Dec. 7, Caris Guardrail won the nation’s best science award, dubbed the Jang Young-sil Award, from the Korea Industrial Technology Association.

The company’s PVC-composite guardrails with a honeycomb structure offer increased strength and elasticity needed to withstand the impact from a vehicle moving at a high speed.

According to the firm, a fluorescent material enables the guardrail to be seen in the dark under low lighting conditions, thereby increasing safety for drivers. Furthermore, the material does not change color after prolonged exposure to the sun’s ultraviolet rays.

The rib-like structure within the walls enables sounds to be absorbed without requiring any additional materials. In addition, the extrusion manufacturing process for the walls forms layers and spaces within the walls, which enhances its ability to efficiently absorb sound.

Being a nonmetal product, the synthetic wall is anticorrosive. To maintain ecological standards, the company says the walls do not incorporate glass wool, unlike many similar products made by other companies.

Out of the company’s several types of PVC products, the CG10 PVC Guardrail is the world’s first PVC guardrail developed with the latest technology. It has better shock absorption while maintaining the strength and performance of steel guardrails.

Furthermore, it is resistant to rust and corrosion for longer initial performance, so it has economic feasibility and contributes to road safety.

One unit of the guardrail weighs 28.2 kilograms, and it can be installed at intervals of 1.5-2 meters of posts.

The CG11 PVC Guardrail was developed with design and solidity that complement the existing 2W Guardrail (CG10). It also has the function of withstanding strong impact and remains free of corrosion in any weather condition.

Meanwhile, the application of the CG20 PVC Guardrail is broader than the CG10, CG11. With a larger size, greater strength and endurance, the CG20 can not only be applied to roadsides, but also to the median strip.

The CG30 PVC Guardrail has a design that helps break the monotony of driving, while the CG40 PVC Guardrail has a roller barrier system for rapidly curved sections.

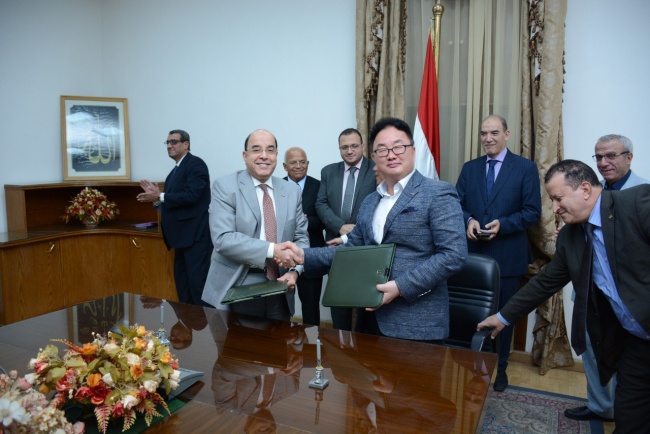

The company has signed export deals with firms in Egypt, Mongolia, Malaysia, Indonesia, China and the Philippines, including an exclusive deal worth about 300 billion won ($266 million) with the Ministry of Military Production of Egypt.

Under the memorandum of understanding, Caris Guardrail will provide the country with PVC-composite guardrails, which will be set up across Egyptian roadways, and build a joint-venture factory there, according to the company.

Upon passing the US collision test this year, the company is pinning hopes on bigger trade volume and more export destinations.

The company highlighted that its goal is to develop a guardrail system that is eco-friendly, cost-efficient, and safer than steel guardrails.

“We have seen how steel guardrails can be faulty in times when we need them to perform. Whether it is piercing through cars or simply not doing the job that a guardrail should do, we believed that a more practical solution was necessary,” it said.

“This is why we dedicated many years to the research and development of our products. The result of all our efforts is our PVC guardrail,” Yu said. “Development of the world’s first and the only product is attributable to our continuous challenge, being unafraid of possible failures.”

The CEO added that Caris Guardrail would contribute to Korea’s competitiveness.

By Kim Yon-se (kys@heraldcorp.com)

![[AtoZ into Korean mind] Humor in Korea: Navigating the line between what's funny and not](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/22/20240422050642_0.jpg&u=)

![[Herald Interview] Why Toss invited hackers to penetrate its system](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=644&simg=/content/image/2024/04/22/20240422050569_0.jpg&u=20240422150649)

![[Herald Review] Xdinary Heroes kicks off five-month-long project with solo concert, teases new album](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=652&simg=/content/image/2024/04/22/20240422050539_0.jpg&u=20240422152154)

![[Today’s K-pop] Illit logs 100m Spotify streams with debut song](http://res.heraldm.com/phpwas/restmb_idxmake.php?idx=642&simg=/content/image/2024/04/22/20240422050650_0.jpg&u=)